Sida mid ka mid ah noocyada ugu muhiimsan ee qalabka processing aluminium, profiles aluminium waxaa si ballaaran loo isticmaalaa berrinkii dhismaha la qurxin gaar ah, dahaarka dhawaaqa aad u fiican, ilaalinta kulaylka iyo recycability, iyo by falimihiisii ka mid ah qaabaynta extrusion ay iyo guryaha farsamo iyo jir sare, conductivity kulaylka wanaagsan iyo xoog gaar ah oo sare, iwm Waa dheeraad ah oo si ballaaran loo isticmaalo in gaadiidka, elektarooniga ah, mishiinada, warshadaha petrovium ah, warshadaha petrovium ah, warshadaha petrovium, warshadaha, warshadaha, warshadaha iftiinka, warshadaha, warshadaha, warshadaha. Maanta, daaWJ-LEANsoo bandhig socodka habka aluminium profiles.

Tallaabada 1: Xulashada alaabta ceeriin

Qalabka aluminium ee warshaduhu waa qaab-dhismeedka warshadaha ee lagu helo kuleylinta usha aluminiumka iyada oo loo marayo naqshadaynta caaryada, iyo usha aluminiumka waxaa lagu tuuraa aluminiumka aluminiumka, kaas oo loo yaqaan 'profile aluminium profile alaabta ceeriin; Alaabta ceeriin waxay si toos ah u saameyn doontaa waxqabadka alaabta aluminium ee warshadaha.

Tallaabada 2: Kuleylinta usha aluminiumka

Daaweynta kuleylka ee usha aluminiumku waa inay hubisaa xakamaynta heerkulka, haddii heerkulku aad u sarreeyo ama aad u hooseeyo, waxay si toos ah u saameyn doontaa adkaanta alaabta la dhammeeyey, markaa heerkulka waa in si adag loo xakameeyaa inta lagu jiro habka kuleylka iyo qaboojinta;

Tallaabada 3: Naqshadaynta caaryada

Aluminium aluminium warshadeed waa sheyga kama dambaysta ah ee ka soo baxa usha aluminiumka ee kuleylinta iyada oo loo marayo caaryada, iyo caaryada waxaa loo qaabeeyey iyadoo loo eegayo baahida leh tilmaamo sax ah oo sarreeya, oo loo isticmaalo in lagu faafiyo qeexitaannada loo baahan yahay iyo qaybta iskudhafka ah ee alaabta profile;

Tallaabada 4: Extrusion aluminium warshadeed

Heerkulka kaxaynta ayaa ah arrin aasaasi ah oo muhiim u ah habka wax-soo-saarka extrusion. Xawaaraha extrusion waa in si taxadar leh loo xakameeyaa inta lagu jiro habka extrusion.

Tallaabada 5: hagaajinta toosinta profile aluminium warshadeed

Toosanaanta aluminium aluminiumku waxay saamaysaa in aluminium aluminium loo isticmaali karo qalabka farsamada, markaa toosnaanta aluminium aluminiumku waa mid ka mid ah heerarka muhiimka ah ee tayada aluminiumka. Guud ahaan, profiles extruded waxay u baahan yihiin in la toosiyo si toos ah.

Tallaabada lixaad: gabowga gacanta

Noocyada aluminium ee ay soo saartay extrusion waxay leeyihiin qallafsanaan hooseeya ka hor da'da oo looma isticmaali karo sida alaabooyinka la dhammeeyey, sidaas darteed guud ahaan, waa inay noqdaan kuwo da 'weyn si loo hagaajiyo xoogga.

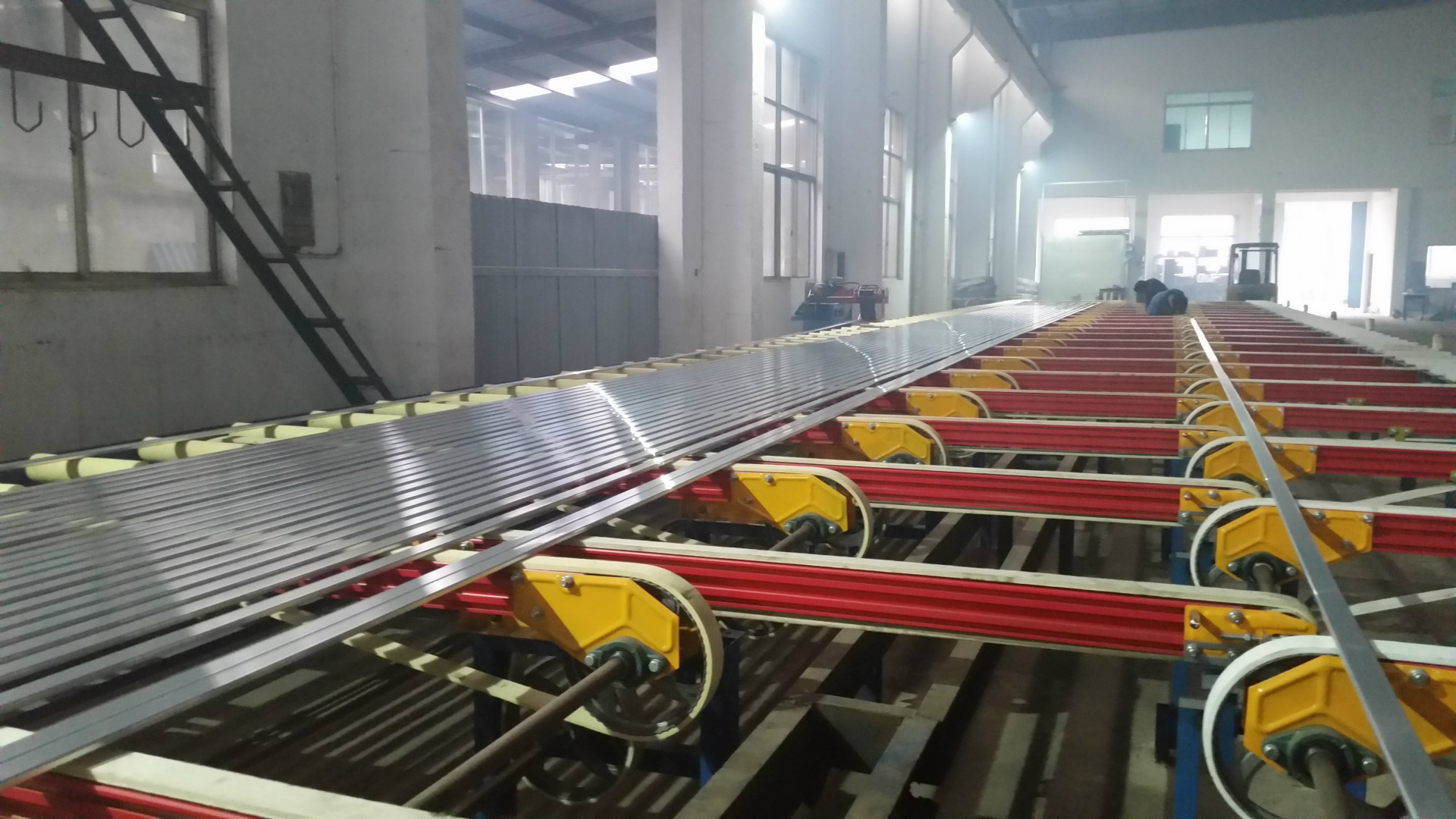

Talaabada 7: Bacaad qarxinta

Ka dib qaabaynta extrusion, dusha sare ee aluminium aluminium ee warshadaha waxay yeelan doonaan khadad fidsan oo cad, iyo micropores dusha sare waa weyn yihiin, xad adag, waana in la ciido.

Tallaabada sideedaad: Daaweynta oksaydheynta dusha sare

Guud ahaan aluminium profile dusha anodized daawaynta cad lacag, xarrago leh oo qurux badan iyo iska caabin daxalka. Guud ahaan tallaabadan samee, ka dib qaboojinta, aluminium aluminium ah oo dhammaystiran ayaa soo bixi doona.

Tallaabada 9: Baakaynta

Sababtoo ah shuruudaha tayada alaabooyinka aluminium ee warshadaha ayaa aad u sarreeya, quruxda guud ee muuqaalka waa mid aad u gaar ah, sidaas darteed shuruuduhu aad bay u adag yihiin baakadaha dambe.

Habka farsamaynta astaanta aluminium ee dhammaatay

Talaabada 1: Jar

Dhererka astaanta aluminiumku guud ahaan waa 6.01 mitir, goynta wanaagsan ee astaanta aluminiumka ayaa loo baahan yahay si waafaqsan sawirada. Qaladkayaga goynta guud waa ≦0.5mm. Marka lagu daro goynta dhererka, aluminium profiles sidoo kale waa la gooyn karaa gees iyo gees.

Talaabada 2: Qod oo taabo ilkaha

Guud ahaan, marka profile-yada aluminiumku ay gudaha ku xiran yihiin, waxaa lagama maarmaan ah in la feero oo la taabto, iyo mindiyaha laydhka ee loo isticmaalo feerka iyo taabashada sifooyinka kala duwan ee aluminium profiles ma aha isku mid. Sidaa darteed, feedhista iyo garaacista sidoo kale waa mid ka mid ah dhinacyada tijaabinta xoogga habaynta ee astaanta aluminiumka.

Tallaabada 3: hagaajinta astaanta aluminiumka

Ka dib goynta iyo qodista, waxaa lagama maarmaan ah in lagu xiro aluminium aluminium xiriiriye aluminium ah. Ilaa iyo inta master-ka rakibaadda si waafaqsan rakibidda sawirada, waxaad samayn kartaa qaabka aluminium ee la doonayo, daboolka qalabka, tuubada shaqada iyo wixii la mid ah.

Adeegeena ugu muhiimsan:

Ku soo dhawoow xigashada mashaariicdaada:

La xidhiidh:info@wj-lean.com

Whatsapp/telefoon/Wechat : +86 135 0965 4103

Mareegta:www.wj-lean.com

Waqtiga boostada: Agoosto-14-2024